Precautions For Composite Geomembrane Construction

① The gravel cushion shall be constructed according to the requirements of the drawings, and the filling thickness shall be 30cm. During the construction, the bulldozer cooperates with the road roller for leveling and rolling. It is strictly forbidden to have hard protrusions such as crushed stones and blocks to prevent the protrusions from penetrating the composite geomembrane during the next construction.

② The sand-gravel cushion should be clean, dry, and have sufficient strength and wear resistance. The particle shape should be free of soft stones and other impurities. The particle size is 20-50mm, and the mud content is not more than 10%.

③ The degree of compaction of the sand-gravel cushion shall reach the degree of compaction of the corresponding subgrade filling. The road arch shall be reserved during the construction process, and the cross slope of the road arch shall be 2%.

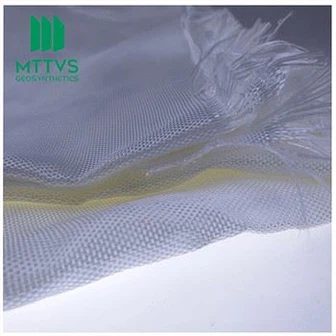

④ The composite geomembrane is composed of two cloths and one membrane. It should be laid outside the toe of the embankment slope. It shall be laid on the flat lower bearing layer according to the bottom width of the full section of the embankment. When paving, it should be straight and flat, close to the underlying layer, and there should be no distortion, folding, or overlap. When paving on a slope, a certain degree of compactness should be maintained, which can be controlled by U-shaped nails.

⑤ In order to ensure the integrity of the composite geomembrane during on-site construction, the overlap method is adopted. The lap length is controlled within 30cm-90cm (50cm is appropriate). The lap joint is fixed with U-shaped nails (U-shaped nails are set every two meters). If the geomembrane is damaged during construction, it must be repaired immediately.

⑥ The composite geomembrane should not be exposed to the sun for a long time to avoid performance deterioration.

⑦ After the geomembrane is laid, the filler should be filled within 48 hours to prevent sun aging. Filling should be carried out symmetrically according to the principle of "two sides first and then middle". It is strictly forbidden to fill the middle of the embankment first.

⑧ The filling material should be soil that has sunk and can be directly rolled (because the first layer of soil on the geomembrane cannot be sunk by a Wuhua plow, so as not to damage the geomembrane and affect the construction quality). It is not allowed to unload directly on the geomembrane, but it must be unloaded on the paved soil surface. The unloading height shall not exceed 1m, and it shall be leveled gradually with a bulldozer.

⑨ All vehicles and construction machinery are not allowed to walk directly on the paved geomembrane.

⑩ Do a good job in the whole process control of on-site technology, attach importance to geomembrane construction, and ensure the quality of on-site construction.